Why Quality Fuel Injection Pump Parts Matter for Engine Performance

Introduction

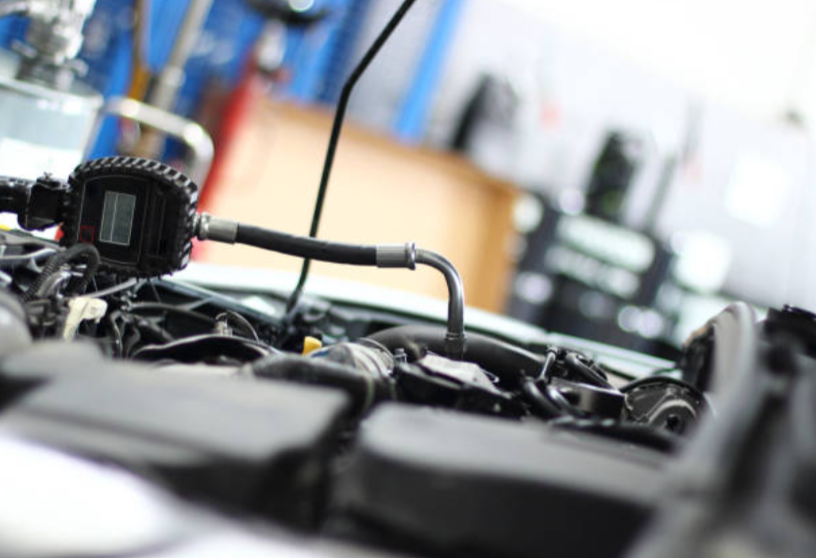

Engines are the heart of any vehicle or machinery, and their performance depends heavily on how efficiently they manage fuel delivery. One of the most critical components in this system is the fuel injection pump. It ensures that the right amount of fuel is delivered at the correct pressure and timing, which directly affects combustion, power output, and fuel efficiency.

Fuel injection pump parts play a crucial role in regulating fuel delivery to an engine, ensuring precise timing, pressure, and combustion efficiency. High-quality parts such as plungers, delivery valves, and seals are essential for smooth performance, better fuel economy, reduced emissions, and longer engine life.

However, the effectiveness of the fuel injection system depends not only on the pump itself but also on the quality of the individual parts that make it up. Using low-quality or worn-out fuel injection pump parts can lead to engine problems ranging from poor performance to costly breakdowns. In this article, we’ll explore why quality fuel injection pump parts are so important and how they impact engine performance.

Understanding the Role of the Fuel Injection Pump

What Does a Fuel Injection Pump Do?

The fuel injection pump is designed to pressurize fuel and deliver it to the engine’s cylinders at the precise moment required for efficient combustion. Unlike older carburetor systems, modern engines rely on injection pumps for greater accuracy, better power control, and improved emissions.

Key Components of a Fuel Injection Pump

A typical fuel injection pump includes several crucial parts, such as:

- Plungers and barrels – responsible for pressurizing fuel.

Delivery valves – regulate fuel flow into the injectors.

Camshaft and tappets – control timing and movement. - Seals and gaskets – prevent leaks and maintain pressure.

The performance of each of these parts collectively determines how well the engine runs.

Why Quality Fuel Injection Pump Parts Are Essential

1. Precise Fuel Delivery

High-quality pump parts ensure that fuel is delivered at the right pressure and in the right amount. Poor-quality or worn components may cause irregular fuel delivery, leading to incomplete combustion, reduced power, and higher emissions.

2. Improved Engine Efficiency

Engines perform best when fuel is atomized correctly and ignited at the optimal time. Quality pump parts maintain this precision, ensuring better fuel economy and smoother engine operation—key benefits for both vehicles and industrial machinery.

3. Longer Engine Life

Low-quality parts wear out quickly and can cause strain on other components of the engine. For example, a leaking seal can reduce pump pressure and damage the injectors. By investing in durable parts, you minimize wear and extend the life of your engine.

4. Reduced Maintenance Costs

Engines with substandard parts require frequent repairs and part replacements. Quality components may cost more upfront, but they save money in the long run by reducing downtime, minimizing failures, and avoiding expensive overhauls.

5. Environmental Compliance

With increasing environmental regulations worldwide, including in Europe and Asia, engine emissions are closely monitored. High-quality fuel injection pump parts help maintain efficient combustion, thereby reducing harmful emissions and ensuring compliance with environmental standards.

The Risks of Using Low-Quality Parts

Poor Engine Performance

Substandard pump parts often result in low fuel pressure, irregular spray patterns, or incorrect timing. This can cause sluggish acceleration, misfires, or reduced power output.

Increased Fuel Consumption

If the fuel pump is unable to regulate fuel delivery properly, the engine may burn more fuel than necessary. Over time, this significantly increases operating costs.

Higher Emissions and Pollution

Incomplete combustion caused by faulty pump parts produces more smoke, carbon deposits, and harmful gases. This not only affects the environment but can also lead to fines or failed inspections.

Costly Engine Damage

In severe cases, defective pump parts can lead to overheating, damaged injectors, or even total engine failure. The cost of repairing or replacing an engine far outweighs the savings from using cheaper parts.

Signs Your Fuel Injection Pump Parts Need Replacement

Knowing when to replace parts is crucial for maintaining performance. Some common warning signs include:

- Difficulty starting the engine.

- Unusual knocking or rattling noises.

- Excessive smoke from the exhaust.

- Drop in fuel efficiency.

- Loss of engine power.

- Leaks around the fuel pump area.

If you notice these symptoms, it’s important to have your pump inspected and faulty parts replaced promptly.

Choosing the Right Fuel Injection Pump Parts

1. OEM vs. Aftermarket Parts

- OEM (Original Equipment Manufacturer) parts are made by the same company that built the original components. They guarantee compatibility and performance but may come at a higher price.

- Aftermarket parts are made by third-party manufacturers. While some are of excellent quality, others may not meet the same standards. Always research and choose reputable brands.

2. Material and Build Quality

Ensure that the parts are made from durable materials that can withstand high pressure and heat. Precision engineering is key to maintaining fuel delivery accuracy.

3. Supplier Reputation

Purchase parts from trusted suppliers with positive reviews and proven track records. In industries like automotive and heavy machinery, reliability is non-negotiable.

4. Warranty and Certification

Look for parts that come with warranties and meet international quality standards. Certifications provide assurance that the parts have undergone proper testing.

Maintenance Tips for Prolonging Fuel Injection Pump Life

- Use clean fuel: Contaminated fuel is one of the leading causes of pump damage. Always use high-quality fuel and change filters regularly.

- Schedule regular servicing: Preventive maintenance helps identify wear and tear before it becomes a serious issue.

- Avoid running on low fuel: Low levels can allow air and debris to enter the pump, causing damage.

- Replace worn parts promptly: Don’t delay repairs when signs of failure appear. Early intervention saves money and protects the engine.

Industries That Rely on High-Quality Pump Parts

Fuel injection pumps are not limited to cars and trucks; they are critical in many industries in Ireland, Europe, and globally:

- Automotive – cars, trucks, buses.

- Marine – boats, ships, and fishing vessels.

- Agriculture – tractors and harvesters.

- Construction – heavy machinery such as excavators and loaders.

- Industrial generators – backup power systems.

For all these sectors, engine reliability directly impacts productivity and profitability.

Conclusion

The performance, efficiency, and longevity of an engine depend greatly on the quality of its fuel injection pump parts. While it may be tempting to cut costs with cheaper alternatives, doing so can lead to poor performance, higher fuel consumption, and expensive engine repairs.

By investing in durable, high-quality components, businesses and vehicle owners not only protect their engines but also save money in the long term through reduced maintenance and improved efficiency. In an age where performance and environmental standards are more important than ever, choosing quality fuel injection pump parts is not just a smart decision—it’s a necessity.