Enhancing Industrial Sound Control with Advanced Acoustic Barriers

1. Introduction

In today’s fast-paced industrial environments, controlling noise is not just about comfort—it’s about compliance, productivity, and protection. Acoustic barriers are essential sound-insulating materials that help reduce airborne noise and minimize impact vibrations. These barrier products are vital in sectors like automotive, construction, HVAC, marine, and public transport, where noise levels can compromise safety, communication, and equipment functionality.

Unlike traditional insulation materials, acoustic barriers offer both sound absorption and transmission loss, making them a preferred choice for managing industrial acoustics. These products can be customized in shape and density to meet the specific demands of diverse applications, and when paired with acoustic foam, they create a powerful laminate that tackles even the most complex noise control challenges.

2. Benefits of Acoustic Barrier Products

Acoustic barriers provide a range of advantages across industries, including:

- Excellent Sound Insulation: Acoustic barriers are designed to prevent sound from passing through panels, improving noise isolation.

- Anti-Vibration Properties: Their dense material structure effectively reduces mechanical vibrations and impact noise.

- Thermal Reflection: Some barrier products include surface coatings or foils that reflect heat, making them ideal for high-temperature environments.

- Customizability: Whether die-cut, water jet cut, or molded, these barriers can be customized to fit curved or complex surfaces.

- Compatibility with Acoustic Foams: Acoustic barriers can be laminated with acoustic foams, enhancing their sound-absorbing capabilities.

Applications of these barrier products range from home appliances and metal furniture to lift cabins, industrial machinery, earth-moving vehicles, and beyond.

3. Types of Acoustic Barriers Available

A. Polymeric Acoustic Barriers (C03 and C09)

These low-density vinyl membranes are loaded with naturally occurring minerals and are free from lead and bitumen. Their primary function is to improve sound insulation in metal, wood, or plastic panels. Installed in close contact with the original panel, they are especially useful in overcoming resonance issues in materials like plywood and hollow-core panels.

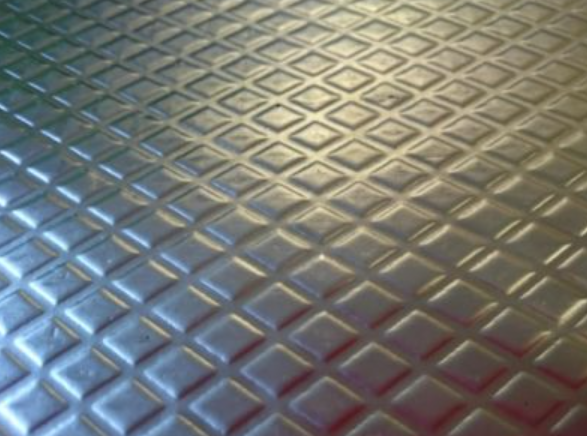

B. Bitumen PE Foil Covered Acoustic Barriers (C022 & C023)

These products feature a black PE face and a self-adhesive backing. Their diamond-embossed surface is effective in flat sound insulation and vibration reduction. The PE foil layer prevents oil seepage and allows bonding with other substrates to form composite materials.

C. Bitumen Aluminium Acoustic Barriers (C024)

This variant is designed for heat-exposed areas such as engine blocks and marine applications. The aluminium foil surface protects against thermal damage while ensuring the barrier continues to dampen sound and vibrations efficiently.

4. Foam Conversion: The Backbone of Customized Acoustic Solutions

Foam conversion refers to the transformation of raw foam materials into customized components suited for various acoustic and structural needs. At Acoustafoam, an extensive in-house setup of CNC machines, laminators, water jets, and die-cutting presses enables the creation of highly tailored solutions.

Foam Types Used:

- Polyurethane Foam: Used for cushions, packaging, and insulation due to its durability and flexibility.

- Polystyrene Foam: Lightweight and ideal for thermal insulation and packaging.

- Polyethylene Foam: Known for moisture resistance and used in padding, packaging, and insulation.

Conversion Processes Include:

- Cutting and Slitting: Achieving precise thickness and shape.

- Laminating: Enhancing material performance by combining foam with barriers or other substrates.

- CNC Profiling: Creating bespoke components for specific industries.

These processes ensure every acoustic component meets technical and functional demands, be it for radiator sound absorption in construction vehicles or heat insulation in yacht engine rooms.

5. Class 0 Foam: Fire-Resistant Acoustic Performance

Class 0 foam is engineered for high-risk environments where fire resistance and sound absorption are equally critical. Treated with a mineral compound to prevent combustion, this foam is ideal for:

- Engine rooms

- Generator canopies

- Military vehicles

- Industrial equipment

Key Benefits of Class 0 Foam:

- Fire-resistant and chemically inert

- Easily molded for curved surfaces

- Available with foil facings for marine or heat-intensive uses

- Non-toxic, flexible, and CFC & HCFC free

- Available with self-adhesive backing

For applications where both thermal insulation and acoustic control are required, Class 0 foam can also be integrated with lead foil and polymeric acoustic barriers for maximum performance.

See also: Top Charlotte Business Brokers to Help You Buy or Sell a Business

6. Where Acoustic Barriers and Foam Conversion Shine

Acoustic barrier products and converted foams find their utility in a wide array of sectors:

- Automotive: Headliners, door panels, engine insulation

- Construction: Wall panels, floor insulation, radiator noise control

- Marine & Boats: Engine bay insulation, cabin comfort

- HVAC Systems: Duct lining and vibration control

- Public Transport & Rail: Noise control in cabins and undercarriage systems

- Medical Sector: Acoustic pads, orthopaedic support foams

- Military Vehicles: Fire-retardant acoustic solutions with high durability

- Industrial Machinery: Enclosures and anti-vibration pads

Each of these sectors benefits from the modularity, performance, and environmental adaptability of barrier and foam-based acoustic solutions.

7. Environmentally Friendly & Quality Assured

Modern foam conversion methods and barrier products increasingly focus on sustainability. Many products are manufactured using eco-friendly or recycled materials to reduce environmental impact. Additionally, Acoustafoam applies rigorous quality control to ensure every batch meets strict industry standards.

By integrating sustainability with performance, these barrier products meet the dual needs of environmental responsibility and acoustic effectiveness.

8. Conclusion: Why Acoustic Barriers Are a Game-Changer

Acoustic barriers and foam conversion technologies are no longer optional—they’re critical components in modern industrial sound management. Whether you’re dealing with engine noise, structural vibrations, or thermal-acoustic challenges, there’s a barrier product that can be tailored to your needs.

The ability to combine these barriers with acoustic foams, Class 0 profiles, and eco-friendly manufacturing ensures you receive a solution that’s safe, efficient, and built to last.

To explore how barrier products and foam conversion can help in your specific project—be it in transportation, construction, or machinery—contact Acoustafoam today. Their team of experts is ready to provide innovative solutions that fit your industry, application, and budget.